~Innovative Manufacturing, Advancing Peptide Medicines~

Yasumasa Watanabe (Mr.)

Marketing Responsible,

Vice President,

Corporate Strategy Department

Mail: y-watanabe@peptistar.co.jp

URL: https://peptistar.com

Please feel free to contact us for any questions, inquiries, etc

Tomoaki Masuda (Mr.)

Department Manager,

Fine Chemicals & International Trading

Mail: tmasuda@mitsubishiingredients.com

TEL: +1-973-368-7708

(You can jump to the page from the below hyperlink)

*In case of Solid Phase Peptide Synthesis

** SPPS: Solid Phase Peptide Synthesis, LPPS: Liquid Phase Peptide Synthesis

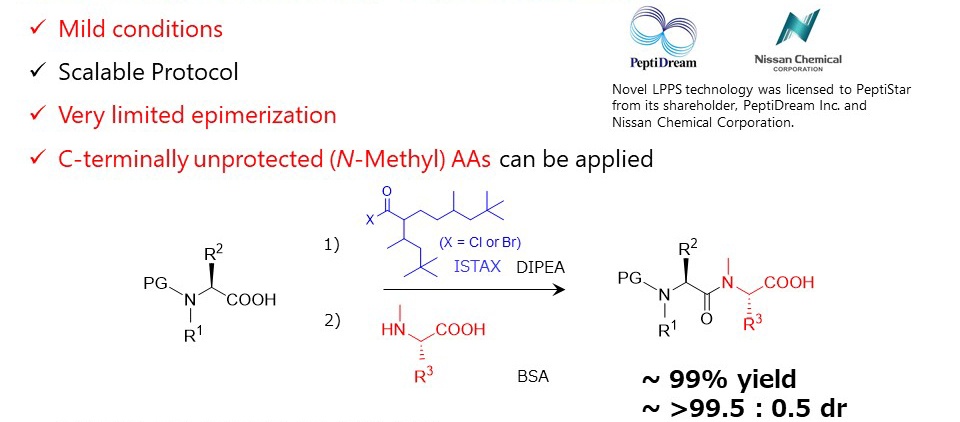

Ref.) Org. Lett. 2020, 22, 20, 8039-8043

https://doi.org/10.1021/acs.orglett.0c02984

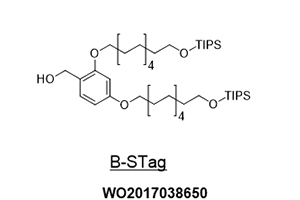

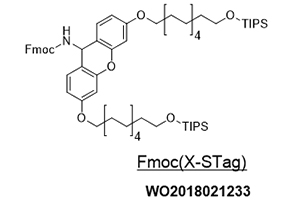

WO2020/189621

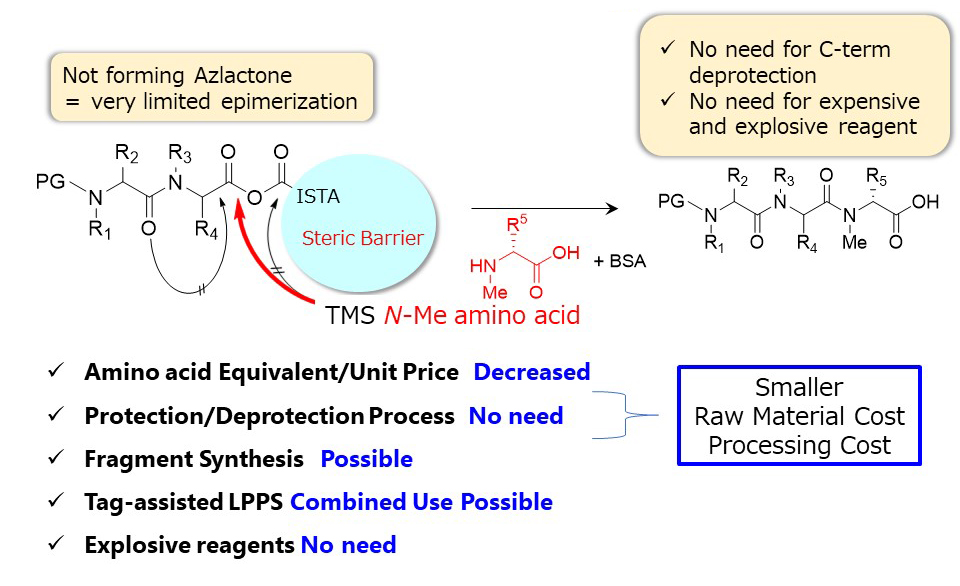

BSA; N,O-bis(trimethylsilyl)acetamide

BSA; N,O-bis(trimethylsilyl)acetamide

Confidential

|

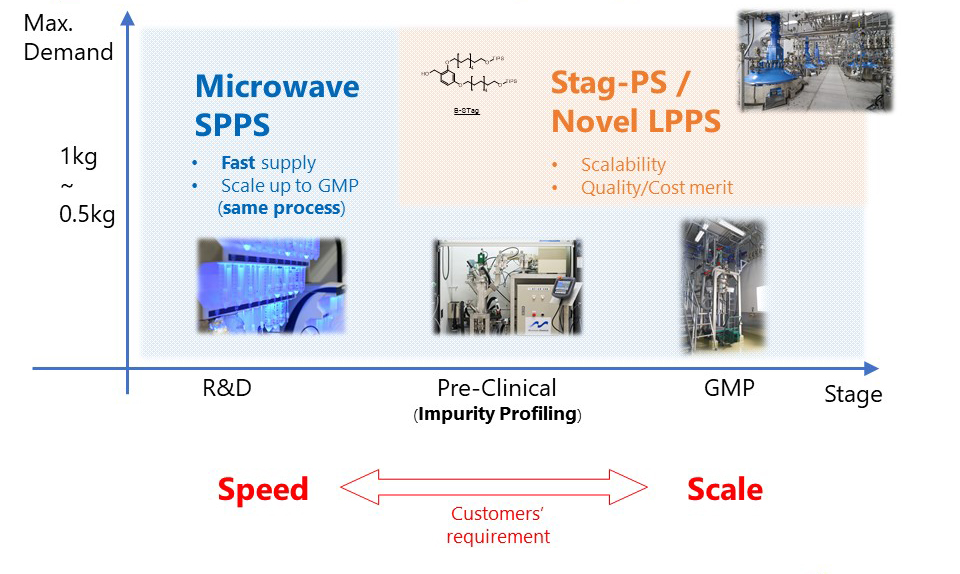

SPPS |

LPPS |

|||

|---|---|---|---|---|

|

Conventional SPPS |

Microwave SPPS |

Stag-PS |

Unprotected LPPS |

|

| Features |

- |

Quick/Uniform heating |

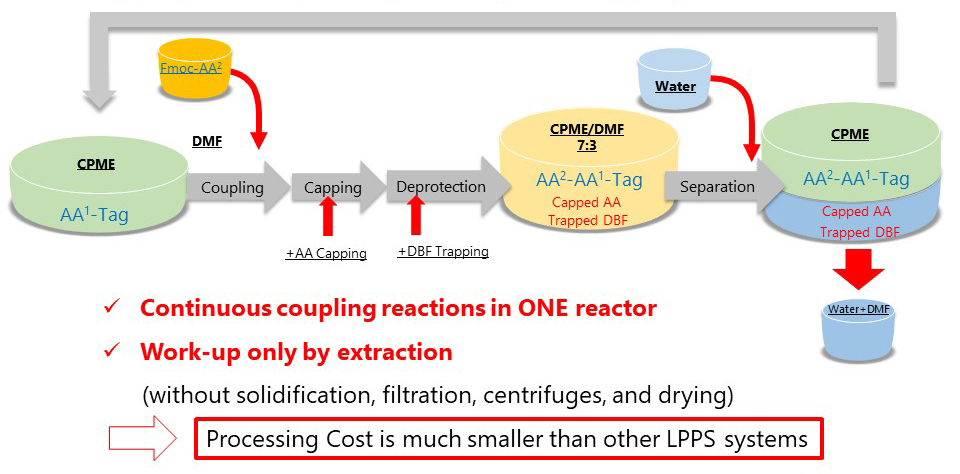

Serial coupling in CPME |

Using Unprotected AAs |

|

AA equivalent |

2-6 eq. |

1.5-3 eq. |

1.2-2 eq. |

1.1-1.5 eq. |

|

AA unit cost |

high |

high |

high |

High - Low |

|

Rxn. Time |

Long |

Short - Middle |

Short - Middle |

Short - Middle |

|

Monitoring |

Qualitative |

Qualitative |

Quantitative |

Quantitative |

|

Fragment Strategy |

- | - | - | Possible |

|

Filter Reactor |

Necessary |

Necessary |

NOT necessary |

NOT necessary |

|

Scale up |

Limited by facility scale |

Limited by facility scale |

Easy |

Easy |

|

Development time |

Short |

Short |

Middle |

Long |

|

【Suitability to each scale】 |

||||

|

Sample |

★ |

★★★ |

☆ |

☆ |

|

Tox. study |

★ |

★★★ |

★★ |

★★ |

|

Clinical Trial |

★ |

★★ |

★★ |

★★ |

|

Commercial |

★ |

★★ |

★★★ |

★★★ |

Confidential

|

Process Development |

Manufacturing |

QC/QA/Regulatory |

|

|---|---|---|---|

|

PeptiStar |

|

|

|